Preparing industrial pumping systems for seasonal temperature shifts is essential for ensuring continuous performance across Houston facilities. As cooler months approach, pumps become more vulnerable to moisture intrusion, thermal fluctuation, and gradual mechanical fatigue. A proactive strategy helps operations reduce unexpected stoppages, manage energy use efficiently, and avoid avoidable failures that disrupt production. This guide offers practical insights to help teams identify early warning signs, strengthen maintenance routines, and plan ahead before temperatures change.

Understanding Temperature-Driven Pump Stress

Cooler seasonal conditions can create expansion and contraction cycles that strain internal pump components. Seal wear, lubrication thinning, and metal fatigue are common issues that emerge when equipment operates under inconsistent temperatures. Operators who monitor vibration shifts, unusual noise patterns, and minor leakage around connections can detect concerns early. Integrating routine system checks with existing maintenance schedules helps extend the reliability of pumping assets while supporting surrounding equipment such as gearbox assemblies and connected drive systems.

Detecting Moisture-Related Risks Early

Humidity changes in Houston’s cooler months often lead to condensation inside pump housings, electrical panels, and bearing enclosures. Moisture accumulation increases the likelihood of corrosion and electrical failures if left unaddressed. Simple steps like ensuring proper ventilation, protecting wiring, and checking gasket integrity reduce exposure. Teams working on adjacent industrial components, such as centrifuge repair or blade equipment assessments, often note that moisture-driven deterioration can accelerate across multiple systems, making early detection essential for continuous uptime.

Strengthening Mechanical Support Systems

Pump performance depends on the surrounding mechanical network functioning correctly. Misalignment, loose mounting bolts, and uneven load distribution frequently appear after seasonal shifts. Realignment procedures, lubrication checks, and vibration monitoring are highly effective for stabilizing operations. In facilities where services like shear blade sharpening or rotating equipment balancing take place, technicians often confirm that small adjustments significantly improve pump stability. Support systems that are routinely inspected ensure pumps continue operating efficiently as temperatures begin to drop.

Preventing Internal Component Wear

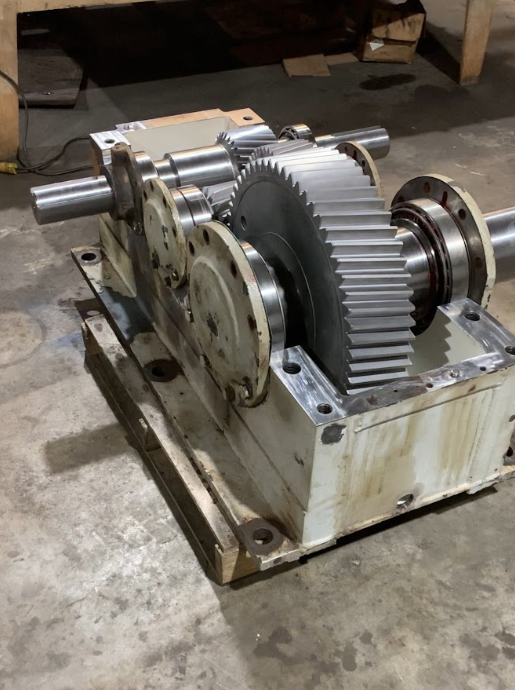

Internal pump components experience stress from gradual friction changes during temperature fluctuations. Regular inspection of bearings, impellers, and diffusers can help catch wear early. Ensuring clean lubrication reservoirs, removing debris, and monitoring surface condition are simple yet effective steps. Facilities that also work with specialized equipment, including Philadelphia gear assemblies or other complex systems, benefit from applying similar wear-prevention principles to all machinery. Preventive attention slows deterioration and protects high-value equipment during cooler seasons.

Scheduling Early Maintenance and Repairs

Planning seasonal evaluations before temperature changes allows teams to identify concerns well in advance. This includes checking for seal integrity, assessing performance levels, and scheduling timely services such as pump repair for any signs of declining efficiency. When maintenance is mapped out early, operational risks are reduced and production schedules remain stable. A structured plan helps teams avoid reactive decisions while ensuring equipment is fully prepared for cooler environmental conditions.

Partnering for Seasonal Reliability

Our commitment to supporting industrial facilities begins with understanding equipment challenges that appear as temperatures shift. Seasonal changes increase the need for dependable evaluations, corrective action, and long-term maintenance planning. Comprehensive solutions protect systems, enhance reliability, and prevent unplanned disruptions as cooler months arrive. The expertise at Hanson Gear Works ensures specialized support for facilities seeking dependable assistance with services such as gearbox repair in Pasadena, Texas, and gearbox repair in Lake Charles, Louisiana, offering tailored guidance for complex equipment requirements. To discuss your specific needs and explore how we can help, call us now or reach out to our team today.