Maintaining consistent productivity in plastics operations requires a proactive focus on extruder gearbox repair and long-term reliability practices. Operators aiming to prevent downtime in plastic manufacturing must understand the early signs of gearbox distress, optimal service intervals, and the most effective approaches to equipment care. When extrusion lines depend on stable torque transfer and smooth output, the gearbox becomes the central point of protection. This blog explores how teams can identify risks, plan maintenance, strengthen repair strategies, and reduce operational interruptions while keeping extrusion machinery running efficiently.

Understanding Early Gearbox Stress Signals

Recognizing the initial indicators of mechanical strain helps teams respond before failures interrupt production. Early warning signs may include abnormal vibration patterns, unexpected drivetrain resistance, and heat concentration around the housing. As extrusion components begin to show fatigue, timely inspection becomes essential for avoiding expensive consequences. Addressing minor inconsistencies also helps prolong the lifespan of precision equipment such as gearbox systems. Operators should note even subtle shifts in noise levels or lubrication behavior, as these often emerge long before a complete breakdown.

Why Routine Maintenance Protects Extrusion Output

Consistent upkeep is one of the most reliable ways to prevent downtime in plastic manufacturing. Regular lubrication checks allow teams to confirm that the internal surfaces are protected from wear and friction accumulation. This also ensures that high-quality components used in gear manufacturing continue to deliver stable performance under demanding conditions. Teams that follow steady maintenance intervals can evaluate load distribution, confirm alignment accuracy, and replace critical wear points before they harm the process. In addition, preventive care supports the longevity of specialized assemblies used in planetary gearbox repair, helping both new and aging machinery meet production standards.

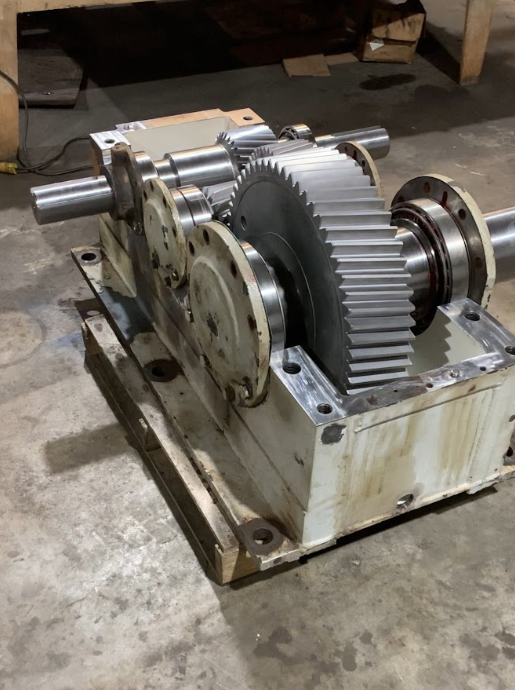

Optimizing Gearbox Repair Strategies for Extrusion Lines

Repair processes should be structured around accuracy, compatibility, and long-term strengthening of internal systems. Technicians repairing intricate components rely on precise measurements to restore torque performance while protecting the motor and screw drive. A strategic repair plan may include surface restoration, component matching, or advanced cleaning techniques to eliminate contamination. Whether teams are focusing on gearbox repair or other rebuild tasks, the goal is to enhance stability and ensure the gearbox supports continuous extrusion output. A methodical repair approach reduces operational strain and extends equipment life.

Supporting Systems That Contribute to Reliable Operation

While the gearbox is central to extrusion performance, several additional systems influence efficiency and alignment. Reliable blade conditioning, such as shear blade repair and shear blade grinding, helps maintain clean cuts and stable material flow. When high-pressure or fluid-based machinery is involved, technicians must verify that supporting assemblies like pump repair components continue to operate smoothly to prevent energy loss. Facilities using shear blades should also incorporate routine checks to ensure consistent trimming and reduce mechanical stress on downstream equipment. Strengthening these supporting systems leads to greater overall extrusion stability.

Advanced Repairs for High-Demand Equipment

Some extrusion environments involve complex, high-capacity machinery where precise restoration becomes even more critical. Teams managing speed reducer repair operations or specialized units such as standard gearbox repair must prioritize accuracy and material compatibility to ensure the equipment withstands continuous operation. Similarly, technicians handling centrifuge repair processes should focus on balance, rotation alignment, and surface protection to reduce energy loss and boost reliability. Incorporating advanced diagnostics allows facilities to identify issues earlier, reduce excessive load on extrusion drives, and support consistent operational output without disruption.

Environmental Impacts That Influence Long-Term Gearbox Performance

Environmental conditions influence how effectively extrusion equipment performs under continuous workloads, especially when temperature changes and airborne contaminants begin affecting lubrication stability. During routine evaluations, technicians often detect mid-operation vibration spikes or torque inconsistencies that point to early internal wear. These findings become more significant when extrusion lines rely on mid-cycle adjustments supported by services such as gearbox repair, which help maintain balanced rotation and reduce mechanical stress.

Strategic Component Upgrades to Strengthen Extrusion Reliability

Component upgrades play an essential role in protecting extrusion performance, particularly when mid-cycle inspections reveal surface fatigue, lubrication inconsistencies, or alignment drift. Technicians often rely on diagnostic readings to decide whether certain parts require resurfacing, material enhancements, or complete replacement to prevent long-term stress accumulation. This process becomes even more effective when production teams incorporate planned upgrades supported by specialized services like planetary gearbox repair and speed reducer repair, ensuring that rotational pathways remain stable under demanding workloads.

Strengthening Operational Reliability Through Professional Support

As production lines face constant pressure, minimizing risk becomes vital for smooth extrusion performance. Organizations managing complex machinery often need dependable support for specialized services, including gearbox repair in Pasadena, Texas, and gearbox repair in Lake Charles, Louisiana, which offer reliable solutions for restoring critical components. When teams require deeper expertise, Hanson Gear Works becomes a trusted partner for advanced restoration, technical precision, and long-lasting mechanical improvements that protect workflow stability. Our approach ensures meticulous attention to detail, tailored service, and dependable craftsmanship that elevate operational confidence. To discuss your specific needs and explore how we can help, call us now or reach out to our team today through our dedicated communication page.