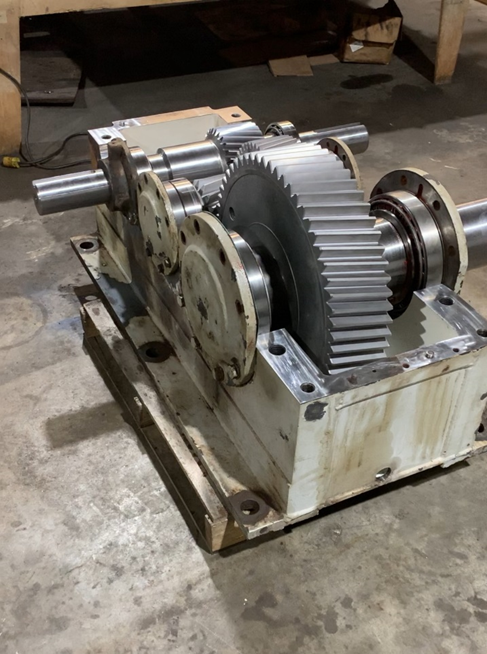

Operators rarely notice the earliest warning signs of gearbox trouble until production grinds to a halt. Gearboxes are designed for heavy-duty performance, but even small irregularities—slight overheating, faint vibration shifts, or unexpected noise—can signal problems building beneath the surface. Left unchecked, these subtle clues escalate into full mechanical breakdowns that halt production lines, damage connected equipment, and lead to costly emergency repairs.

Recognizing Heat as a Red Flag

One of the most telling indicators of gearbox distress is excessive temperature rise. While gearboxes naturally generate heat during operation, consistent overheating points to lubrication breakdown, misalignment, or overloading. Infrared temperature checks and IoT-based sensors can provide early insights, allowing maintenance teams to intervene before components seize or fail entirely.

Listening for Abnormal Noise Patterns

Gear teeth are engineered for precision contact. When you hear grinding, whining, or knocking, it often indicates wear, insufficient lubrication, or misaligned shafts. These sounds tend to develop gradually, which is why many operators dismiss them as “normal machine noise.” Paying attention to changes in pitch or frequency is key to early detection.

Vibration Analysis as a Predictive Tool

Unusual vibration patterns often point to imbalances, misalignment, or worn bearings. Excessive vibration accelerates wear across the entire gearbox assembly, shortening its lifespan. Routine vibration analysis can highlight these shifts early, giving technicians a chance to correct root causes before the damage spreads.

Lubricant Inspections Reveal Hidden Problems

Lubricant condition is a direct reflection of gearbox health. Metal particles in oil samples can indicate gear tooth wear, while discoloration may reveal contamination or overheating. Regular oil analysis not only extends the life of the lubricant but also helps predict failures long before they occur.

Preventive Action Saves More Than Repairs

Spotting these early warning signs is only half the battle—responding quickly is what protects operations. Scheduled inspections, precision alignment, and timely lubrication management significantly reduce unplanned downtime. More importantly, proactive attention prevents costly cascading failures in motors, pumps, and production equipment connected to the gearbox.

Take Action Before Small Issues Become Failures

Every gearbox problem begins with subtle signs. Operators who learn to recognize temperature spikes, unusual noise, and abnormal vibration protect not only their gearboxes but their entire production system. With expert support from Hanson Gear Works, these small warnings can be turned into opportunities for prevention rather than costly downtime.

Even the most vigilant in-house team benefits from specialized gearbox expertise. Our technicians combine advanced diagnostic tools with decades of field experience to pinpoint issues that standard checks may overlook.

Whether addressing gearbox overheating, vibration, or wear-related failures, our repair and rebuilding services are tailored to restore equipment performance while reducing long-term operating costs.

Call Hanson Gear Works today to schedule a professional gearbox inspection and prevent failures before they stop your operations.