Gearboxes are the mechanical backbone of heavy industrial operations, transferring power, controlling speed, and maintaining torque under extreme loads. In steel mills, plastics manufacturing, energy facilities, and material handling environments, gearbox failure can bring production to a costly halt. Understanding why gearboxes fail—and how those failures can be prevented—is critical to maintaining reliability, safety, and profitability.

At Hanson Gear Works, we see recurring failure patterns across industries. Below are the seven most common gearbox issues in heavy-duty applications, along with practical, proven steps that help prevent unplanned shutdowns and extend equipment service life.

1. Overheating From Lubrication Breakdown

Excessive heat is one of the earliest indicators of gearbox distress. When lubrication degrades or becomes contaminated, friction increases rapidly between gears and bearings. Heat accelerates oil oxidation, further reducing viscosity and load-carrying capacity. In severe cases, overheating can cause surface hardening to fail, leading to scuffing or seizure that demands immediate David standard gearbox repair intervention.

Preventing overheating starts with selecting the correct lubricant grade and ensuring oil cleanliness. Regular oil analysis identifies contamination, viscosity loss, or metal particles before damage escalates. Maintaining proper oil levels and cooling airflow also plays a major role in thermal control.

2. Shaft and Gear Misalignment

Misalignment occurs when shafts or gear meshes are not positioned correctly during installation or after long-term operation. Even minor misalignment concentrates stress on limited tooth contact areas, accelerating wear and causing vibration. This condition frequently precedes bearing failure and cracked gear teeth, especially in high-torque systems requiring speed reducer repair.

Precision alignment during installation is essential. Laser alignment tools, foundation checks, and routine vibration monitoring help identify early misalignment. Correcting alignment proactively prevents cascading failures throughout the drive train.

3. Worn or Broken Gear Teeth

Gear teeth wear gradually under load, but improper lubrication, shock loading, or material defects can accelerate damage. Once tooth profiles degrade, load distribution becomes uneven, increasing the risk of tooth fracture. Facilities relying on continuous operation often experience this issue before scheduling proper gearbox rebuilding.

Preventive measures include monitoring gear mesh patterns, maintaining correct backlash, and addressing load spikes caused by process variability. Periodic inspections during planned shutdowns allow worn gears to be replaced before catastrophic failure occurs.

4. Bearing Fatigue and Failure

Bearings support rotating shafts and maintain alignment under load. Over time, fatigue can cause pitting or spalling on bearing surfaces, increasing noise and vibration. Contamination, improper preload, or lubrication starvation shortens bearing life dramatically, often triggering secondary planetary gearbox repair needs.

Using high-quality bearings rated for the application is critical. Clean assembly practices, proper preload settings, and routine vibration analysis significantly reduce the likelihood of unexpected bearing failure.

5. Seal Failure and Contamination

Gearbox seals prevent lubricant loss and keep contaminants out. When seals fail, dust, moisture, or process chemicals enter the housing, compromising lubrication quality. Seal degradation is a leading contributor to premature gearbox failure and often necessitates comprehensive gear manufacturing solutions to replace damaged components.

Routine seal inspection and timely replacement are essential. Selecting seal materials compatible with operating temperatures and environmental conditions extends service life and protects internal components.

6. Shock Loads and Process Overloads

Heavy industries often experience sudden load changes from material jams, start-stop cycles, or process upsets. These shock loads exceed design limits and introduce microfractures in gear teeth and shafts. Over time, cumulative stress results in cracking or catastrophic failure, particularly in aging gearbox systems.

Installing torque limiters, soft-start drives, and overload protection devices helps absorb transient loads. Reviewing operating procedures and training personnel to minimize abrupt starts also reduces mechanical stress.

7. Poor Maintenance and Inspection Practices

Many gearbox failures stem not from design flaws but from inconsistent maintenance. Skipped inspections, delayed oil changes, and ignored warning signs allow small issues to escalate into major breakdowns. Facilities facing repeated failures often require specialized Philadelphia gearbox repair expertise to restore reliability.

Implementing structured preventive maintenance programs is the most effective defense. Scheduled inspections, oil analysis, vibration monitoring, and documented service histories create visibility into gearbox health and support data-driven decision-making.

Partner With Houston’s Gearbox Experts

At Hanson Gear Works, we understand that gearbox failures are more than mechanical problems—they are production risks that affect safety, output, and profitability. Since 1998, we have built our reputation as a trusted partner for heavy industries that depend on precision, durability, and rapid turnaround when equipment performance is compromised.

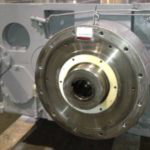

Our facility is fully equipped to handle complex industrial services, including Extruder, David, and advanced Planetary gearbox repair for high-torque applications. Every repair is approached with detailed inspection, metallurgical evaluation, and exacting rebuild standards to ensure long-term reliability—not temporary fixes.

We also support complementary industrial services such as shear blade sharpening, shear blade repair, and centrifuge repair, allowing us to serve as a single, dependable repair partner for critical rotating equipment. Our technicians routinely work with demanding systems requiring pump repair and precision alignment where downtime must be minimized without sacrificing quality.

Transparency and craftsmanship define our work. You can review real examples of our completed projects and repair capabilities in our Gallery to see the level of detail we bring to every job. Whether your operation requires emergency service or planned gearbox rebuilding, we deliver solutions that meet OEM standards and real-world operating demands.

If your equipment shows signs of overheating, wear, or misalignment, don’t wait for failure to dictate your schedule. Call Now to speak directly with our experienced team and keep your operation moving with confidence.